For decades, U.S. telecommunications carriers delivered key universal services to both urban and rural areas. Regardless of cost or efficiency, these federal requirements ensured residents had access to voice, emergency services, and basic connectivity. They also resulted in the continued deployment of legacy infrastructure far longer than originally planned.

This long-standing regulatory landscape is changing. Recent federal relief frameworks allow carriers to retire certain obligations and accelerate network modernization. Even so, carriers can’t shut down legacy systems overnight, and newer platforms must coexist with older infrastructure during the interim. The result is a transitional period where reliability, continuity, and technical pragmatism matter as much as innovation.

What Modernization Actually Means for Telecom Networks

Industry observers often frame telecom modernization as a direct leap from legacy platforms to cloud-native, disaggregated architectures. In practice, the transition is far more incremental, illustrated by the move away from copper- and TDM-based systems toward IP/MPLS-based infrastructure.

This evolution reflects both technical and economic realities. For more than two decades, carrier capital investment focused on wireless expansion and fiber deployment, while older wireline platforms were maintained primarily to meet regulatory and operational requirements.

As growth in traditional revenue streams slows, carriers are increasingly prioritizing cost optimization and efficiency. These efforts include retiring obsolete systems and extending the useful life of platforms that continue to play a critical role in the network. IP/MPLS occupies that middle ground. It is modern enough to support high-capacity optical transport, Ethernet aggregation, and packet-based services, yet mature enough for many platforms to have been in service for 15 years or more.

Why Modern Network Repair Requires Full-System Labs

Maintenance and repair become more complex as telecommunications networks evolve. Modern IP/MPLS platforms reflect these advances through modular, chassis-based designs composed of line cards, switching fabrics, control processors, power supplies, and optical interfaces.

Because effective repair demands full-system visibility, Fortress Solutions operates specialized labs that support IP/MPLS platforms and other core network technologies. These labs enable engineers to test suspect cards in known-good chassis, monitor system-level behavior, and determine whether faults originate at the component level or from broader system interactions.

Although some equipment arrives with a “no trouble found” condition, engineers must still perform verification, burn-in testing, and validation before redeployment. In other cases, subtle faults only emerge under sustained operation, necessitating extended test cycles.

The labs also support product introduction across both newer and mature platforms. OEMs may no longer provide documentation, or existing materials may be incomplete or outdated. Understanding how these systems behave, where they fail, and how they can be repaired requires controlled environments, repeatable testing, and hands-on engineering expertise.

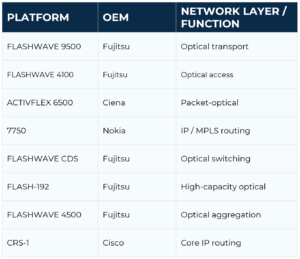

The table below highlights representative platforms used in Fortress Solutions labs across IP/MPLS and optical network layers.

Reverse Engineering, Repairing, and Building What No Longer Exists

When OEM support ends, replacement components disappear from conventional supply chains. Subsequent failures force carriers to either accept increased operational risk or rebuild what the market no longer supplies.

This is where extensive engineering capability is essential. Fortress Solutions lab teams include embedded engineers, power specialists, board designers, and engineers with ASIC-level expertise. When a failure is isolated to a specific component, such as an optical ASIC or power subsystem, targeted replacement often restores full functionality. If that option is no longer viable, entire boards must be reconstructed from the component level.

Fortress Solutions rebuilds optical boards with ASICs designed in-house to support platforms that will remain in production networks for another five to ten years. While chassis redundancy exists, the absence of available spares means a single failure can expose the network to unacceptable risk. By reverse engineering, rebuilding, and redesigning critical components, Fortress helps carriers maintain continuity between planned lifecycles and operational reality.

Looking Ahead: From IP/MPLS to Disaggregated Infrastructure

Although reverse engineering extends the operational life of existing platforms, the telecommunications industry is moving toward disaggregated, software-driven infrastructure built on commercial off-the-shelf (COTS) hardware platforms. This shift increasingly relies on interchangeable white box systems, where standardized hardware is paired with software-defined network (SDN) functions.

In these deployments, logistics, sparing, and rapid replacement of modular components replace traditional board-level repair. Notably, Fortress Solutions already supports this operating model, working with partners through integration, system validation, and staging.

Recent collaboration with companies such as Airspan and Mavenir highlights this evolution. Fortress Solutions provides assembly and testing support for Open RAN and disaggregated systems alongside its established repair capabilities. These partnerships demonstrate how the company’s business model continues to adapt as network architectures change.

Conclusion: Modernization Without Disruption

Telecom networks aren’t rebuilt overnight. Universal service obligations shaped the past, IP/MPLS defines the present, and disaggregated platforms will determine what comes next. Across each phase, the challenge remains the same: maintaining uptime while change is underway.

By combining lab-based repair, reverse engineering, and lifecycle-focused support, Fortress Solutions enables carriers to modernize without disrupting the critical services their networks still depend on. In an industry defined by protracted transitions and overlapping technologies, this capability is increasingly essential.